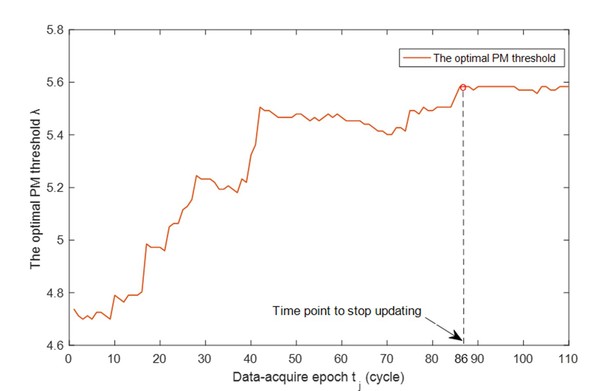

The wear of a cutting tool can lead to tool failure and product quality deterioration, and thus timely maintenance of tools is crucial. Meanwhile, the wear of tools from a same population usually exhibits heterogeneous patterns. Therefore, this paper proposes a dynamic condition-based maintenance (CBM) policy for heterogeneous-wearing tools with considering the product quality deterioration caused by tool wear. The tool wear is modelled by an Inverse Gaussian (IG) process, and the wear rate is assumed to be a random variable to characterize the heterogeneity among tool wear processes. The posterior distribution of reciprocal of tool wear rate is dynamically estimated using the online wear data based on a Bayesian approach. Moreover, the impact of tool wear on product quality deterioration is modelled. The IG process is discretized into a discrete time Markov chain (DTMC). Under the frame of the DTMC, a cost function, containing product quality loss, preventive maintenance (PM) cost and corrective maintenance cost, is developed to determine the optimal PM threshold. The cost function updates dynamically with the dynamic estimation of tool wear rate and thus enables the optimal PM threshold to be dynamically revised. The effectiveness of the proposed CBM policy is demonstrated through a case study.

Figure. The optimal PM thresholds at consecutive data-acquire epochs

If you are interested in the research, please read the paper:

Biao Lu; Yumei Luo. 2024. A dynamic condition-based maintenance policy for heterogeneous-wearing tools with considering product quality deterioration. International Journal of Production Research. Doi.org/10.1080/00207543.2024.2318489.

A full version of this article could be viewed at:

https://doi.org/10.1080/00207543.2024.2318489

Nanjing University of Aeronautics and Astronautics

Copyright 2017 | All Rights Reserved with NUAA